Key Takeaways

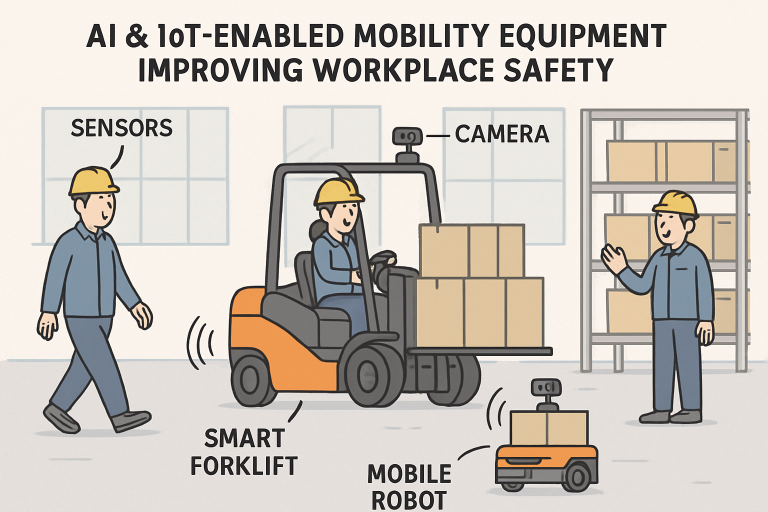

- Smart mobility equipment integrates advanced technologies to improve workplace safety.

- AI and IoT play crucial roles in monitoring and preventing potential hazards.

- Real-world applications demonstrate significant reductions in workplace incidents.

Table of Contents

- Introduction

- AI and IoT Integration in Mobility Equipment

- Wearable Technology: A New Frontier in Safety

- Real-World Applications and Case Studies

- Benefits of Smart Mobility Equipment

- Challenges and Considerations

- Future Trends in Workplace Safety

- Conclusion

Introduction

Smart mobility equipment transforms the industrial landscape by combining traditional safety methods with predictive, data-rich technologies. These systems safeguard staff and assets in real time, foreseeing risks and automatically intervening. This subtle difference is shaping a safer industrial landscape worldwide. In an era of faster-paced environments, worker protection remains a non-negotiable priority. Integrating innovative mobility equipment, such as AI-guided vehicles, intelligent sensors, and connected tools, has reduced workplace hazards and transformed efficiency and operational standards. Industrial ecosystems increasingly rely on innovative solutions like plate casters, which play a critical role in the mobility of smart equipment and machinery across factory floors and warehouses. Smart mobility and connected hardware are revolutionizing workplace safety strategies by leveraging advanced technologies to anticipate and neutralize threats before incidents occur. This shift from reactive to proactive safety strategies results in fewer accidents, improved morale, and significant savings on downtime and insurance costs. Adopting robust mobility solutions and components like plate casters is an investment in productivity and safety, as organizations seek to modernize their operational environments.

AI and IoT Integration in Mobility Equipment

Integrating Artificial Intelligence (AI) and the Internet of Things (IoT) in mobility equipment transforms workplace safety from the ground up. AI-powered platforms aggregate and interpret mountains of operational data, revealing patterns that human supervisors might otherwise miss. Meanwhile, IoT connectivity ensures that everything from forklifts to mobile shelving units is equipped with sensors and trackers, monitoring conditions and status in real time.

For example, smart forklifts equipped with 360-degree cameras, proximity sensors, and AI processing units can autonomously adjust routes to avoid obstacles or pedestrians. This reduces the potential for accidents due to blind spots or operator inattention. Mobile robots and automated guided vehicles (AGVs), often riding atop sturdy plate casters for smooth navigation, can adapt to floor layouts and changing workflows, further minimizing risky maneuvers. The real-time data sent by these pieces of equipment enables supervisors to address threats instantly, dramatically lowering accident rates and injury claims.

Wearable Technology: A New Frontier in Safety

Wearables are rapidly changing the personal safety landscape, offering tools for both monitoring and real-time intervention. Devices like smart helmets, safety vests with embedded biometric sensors, and position-tracking badges provide managers and safety teams with unprecedented insight into worker well-being and location. Many of these devices alert wearers and supervisors if fatigue, overheating, or hazardous environmental conditions are detected, enabling immediate responses to health threats.

Encouraging Safer Ergonomics and Movement

On the shop floor, wearables now proactively address risks like repetitive strain and overexertion. According to data from Occupational Health & Safety, these solutions have reduced injury rates where adopted, as they nudge workers toward safer lifting techniques and provide supervisors with anonymized trend reports. Companies can address sudden incidents and long-term health risks by deploying wearables as part of a broader mobility equipment modernization effort.

Real-World Applications and Case Studies

Industry-leading organizations are already experiencing the tangible impact of smart mobility equipment. One notable example is CNH Industrial, which uses AI-powered ergonomic assessment tools at several manufacturing locations. The company’s system analyzes workers’ movements, flags risky postures, and delivers actionable recommendations, cutting the time needed for ergonomic assessments and directly improving worker health outcomes.

In mining and heavy construction, environmental monitoring PPE helps track exposure to gases, temperature swings, and movement within hazardous zones. Real-time alerts make it possible to evacuate or intervene before conditions become critical, according to reporting from Reuters. These innovations, when built into mobility solutions such as carts, tuggers, and transport systems, ensure that safety protocols are seamlessly woven into every aspect of work.

Benefits of Smart Mobility Equipment

- Enhanced Safety: Instant alerts, machine learning-driven predictions, and automated controls together create a safer work environment for all employees.

- Increased Efficiency: Smart equipment minimizes downtime and streamlines workflows by preventing accidents before they occur, resulting in higher overall productivity.

- Data-Driven Decisions: Real-time performance and risk data help employers refine safety strategies and respond dynamically to evolving operational hazards.

Challenges and Considerations

- High Initial Costs: Upgrading to smart mobility equipment often involves a significant capital outlay. However, many organizations recoup these costs through reduced insurance premiums and lower incident-related expenses.

- Training and Change Management: Employees and managers must be adequately trained to use and maintain new equipment, requiring a structured change management approach.

- Privacy and Data Security: Continuous health and location monitoring invites important conversations around data ownership, privacy, and digital security. Companies must deploy clear policies and robust protections to build trust and ensure regulatory compliance.

Future Trends in Workplace Safety

- Exoskeletons: According to Wikipedia, next-generation wearable robotics will allow workers to safely lift heavier loads, reducing strain injuries and fatigue.

- Augmented Reality (AR): The latest AR headsets and glasses overlay safety warnings, maintenance instructions, and hazard zones directly into workers’ fields of vision, maximizing awareness in real time.

- Advanced Predictive Analytics: AI models will harness increasingly complex operational data to predict and even prevent accidents in sprawling industrial settings with even greater accuracy.

Conclusion

Smart mobility equipment has ushered in a new era of workplace safety, providing the tools and insights necessary for proactive risk management and operational excellence. The strategic deployment of connected devices, advanced machinery, wearables, and specialized components like plate casters is helping industries minimize hazards and elevate worker protection. As technology evolves, adopting these transformative solutions positions organizations to build cultures of safety and innovation, where employees, assets, and business performance are all safeguarded against the unpredictable challenges of the modern industrial world.

You May Also Read: WhyChoosePro.com: Find Trusted Pros Fast!