Table of Contents

- Automation and Robotics

- Artificial Intelligence and Machine Learning

- Industrial Internet of Things (IIoT)

- Digital Twins

- Sustainable Manufacturing Practices

- Personalization and Mass Customization

- Enhanced Supply Chain Visibility

- Conclusion

Consumer goods manufacturing is undergoing a seismic transformation, driven by a surge of technological innovation rapidly redefining the landscape of modern industry. Advancements in automation, analytics, and connectivity—combined with the integration of artificial intelligence and data-driven tools—enable producers to optimize their production lines, enhance agility, and deliver products tailored explicitly to dynamic consumer demands. One essential driver of these sweeping improvements is manufacturing software for consumer goods. It empowers companies to digitize their operations, gain real-time insights, and facilitate continuous improvement across every stage of their production lifecycle. Companies prioritizing these technological upgrades are increasingly well-positioned to adapt quickly to shifting market trends and consumer preferences, helping them stay one step ahead of the competition.

With global competition intensifying and modern consumer expectations on the rise, manufacturers are turning to innovative technologies to boost efficiency and maintain their edge in an increasingly demanding market. Leveraging advanced manufacturing software for consumer goods allows organizations to streamline complex workflows—from real-time inventory management and on-the-fly production adjustments to predictive maintenance routines—helping reduce operational costs and human error while increasing transparency throughout the manufacturing process. This transformative technological shift sets the foundation for more intelligent, flexible factories, resilient supply chains, and reliable, sustainable growth strategies that will shape the industry for years.

Automation and Robotics

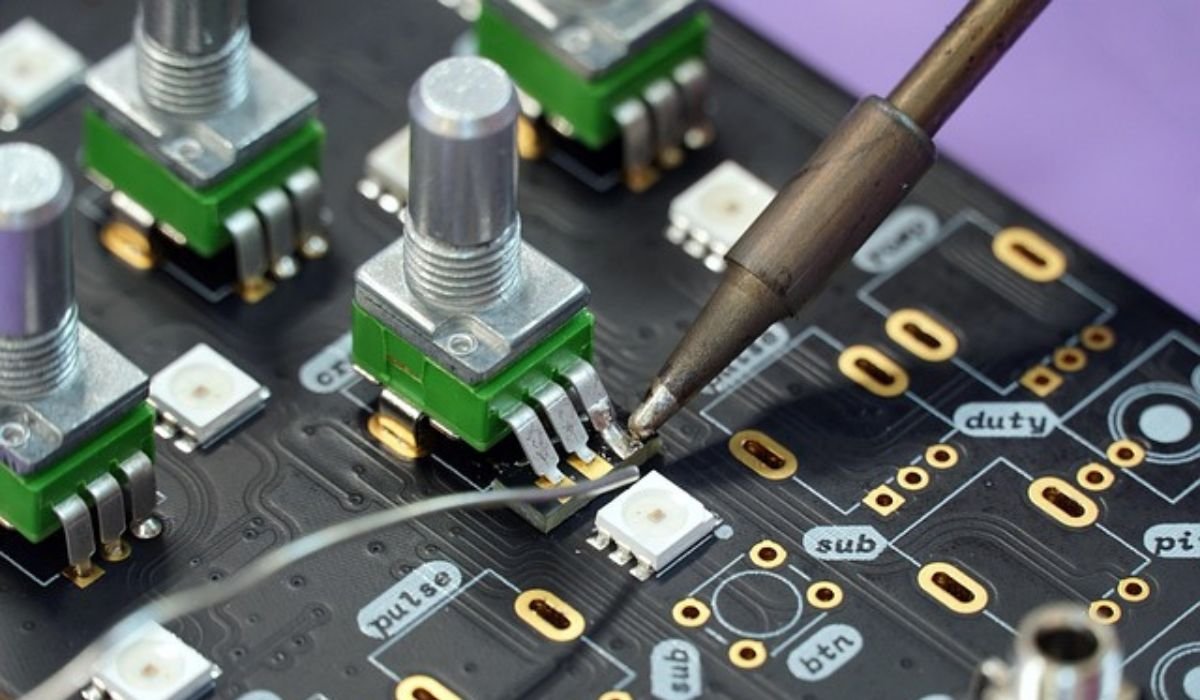

Integrating automation and robotics fundamentally reshapes manufacturing floors worldwide, becoming a staple in modern production environments. Advanced robotics can execute repetitive, high-precision, or hazardous tasks with accuracy that surpasses human capability, ultimately increasing throughput while ensuring consistent quality standards. Automated guided vehicles (AGVs), collaborative robots (cobots), and next-generation robotic arms have become indispensable, streamlining packaging, assembly, and logistics operations, minimizing human error, and driving down long-term operational expenses. Automation is instrumental in helping companies respond swiftly to fluctuating market demands and address persistent labor shortages, making it possible for manufacturers to scale their production and meet tight delivery deadlines for high-volume orders. Additionally, robotics helps create safer workplaces by allowing human workers to focus on creative or complex problem-solving, rather than manual or dangerous labor.

Artificial Intelligence and Machine Learning

Artificial Intelligence (AI) and Machine Learning (ML) are redefining decision-making and process optimization on the factory floor. Machine learning algorithms can sift through enormous volumes of real-time production and market data to accurately forecast demand trends, monitor equipment health, and develop proactive maintenance schedules that prevent costly breakdowns and production delays. AI-driven quality assurance systems closely inspect products as they move down the assembly line, flagging even the slightest defects or deviations from industry standards, thus safeguarding brand reputation. According to McKinsey, organizations prioritizing AI adoption in manufacturing see notable reductions in operating costs and material waste while achieving remarkable improvements in process efficiency and product quality. These technologies are also helping businesses stay compliant with evolving regulatory requirements and respond quickly to unexpected changes in consumer behavior.

Industrial Internet of Things (IIoT)

The Industrial Internet of Things (IIoT) unlocks unprecedented connectivity and data exchange levels within the factory environment. IIoT-enabled sensors, devices, and machinery constantly transmit real-time data to centralized platforms or cloud-based systems, allowing plant operators to monitor key performance metrics, track production progress, and diagnose equipment issues as they arise. This instant feedback enables predictive and preventive maintenance routines, optimizing asset utilization and reducing unplanned downtime and costly emergency repairs. Furthermore, the granular insight gained from IIoT technology allows manufacturers to minimize waste, improve resource allocation, and enhance energy efficiency—ultimately supporting profit margins while reducing environmental impact. Leading industry voices have highlighted IIoT as a game-changer for developing more intelligent, agile factories capable of adapting to operational challenges and shifting customer requirements in real time.

Digital Twins

Digital twins—virtual models that mirror physical products, machinery, or entire production systems—revolutionize product development and continuous process improvement. By leveraging digital twins, manufacturers can simulate new product designs, conduct rigorous testing in virtual environments, and predict customer reactions long before a physical prototype is produced. This dramatically reduces the cost, risk, and time investment of traditional research and development cycles. Leading companies such as Colgate-Palmolive are already applying digital twins to gather direct consumer feedback and accelerate time to market for innovative new products, illustrating this approach’s immense potential in streamlining R&D workflows and ensuring each product meets—or even exceeds—consumer expectations. Integrating digital twins into factory operations enables teams to identify and resolve inefficiencies, allowing for more agile operations and product innovation.

Sustainable Manufacturing Practices

Today’s consumers favor brands prioritizing sustainability, compelling manufacturers to seek new ways to minimize resource consumption and reduce their overall environmental impact. Cutting-edge data analytics platforms are enabling companies to pinpoint areas where energy, water, and raw materials can be conserved throughout the production cycle, while advances in recyclable, renewable, and biodegradable materials are helping to close the loop on waste and support greener operations. Furthermore, many organizations are adopting circular economy strategies by recycling production waste streams and re-engineering products for easier disassembly, repair, or reuse at the end of life. This steadfast commitment to sustainability does not just fulfill regulatory or compliance obligations—it establishes an emotional connection with environmentally conscious consumers, builds brand trust, and inspires stakeholder loyalty. Businesses that weave sustainability into their core operations are better equipped to meet evolving market expectations and regulatory mandates in an increasingly eco-aware global economy.

Personalization and Mass Customization

Personalization is fast becoming the norm in consumer goods, with shoppers seeking unique products tailored to their tastes and lifestyles. Modern technologies such as AI-driven analytics and advanced 3D printing allow manufacturers to offer mass customization while maintaining production efficiency and reasonable costs. AI analyzes consumer data streams from online browsing, purchase histories, and social media, providing actionable insights into emerging trends and facilitating the rapid design of new products. Meanwhile, 3D printing delivers the flexibility to produce custom shapes, sizes, and packaging for individual consumers or niche groups—without disrupting large-scale production lines. This fusion of automation and personalization means manufacturers can deliver unique, meaningful shopping experiences at scale, strengthening customer engagement and fostering brand loyalty in an increasingly crowded marketplace.

Enhanced Supply Chain Visibility

Robust supply chain analytics platforms are unlocking unprecedented transparency, agility, and risk resilience for manufacturers. AI-enabled solutions aggregate data from across the supply network—encompassing suppliers, logistics providers, warehouses, and retail partners—to provide a unified, real-time view of supply chain health and performance. This comprehensive visibility allows businesses to identify and address potential bottlenecks, monitor product movements, benchmark supplier performance, and accurately anticipate demand fluctuations. In the event of a disruption, AI-driven contingency tools generate actionable recommendations, keeping production lines running smoothly and helping to avoid costly downtime. Read more about how these digital innovations are revolutionizing global supply chains, empowering manufacturers to deliver products reliably, on time, and at scale—even during market volatility or external challenges.

Conclusion

Adopting advanced technologies is essential for organizations aiming to thrive in the rapidly evolving world of consumer goods manufacturing. Embracing automation, AI, IIoT, digital twins, and sustainable practices delivers more efficient production and aligns with shifting market expectations for speed, product quality, and environmental responsibility. As innovative digital solutions accelerate, those ready to strategically integrate these emerging technologies will be best positioned for long-term success, industry leadership, and a future defined by adaptability, resilience, and customer-centricity.